- Overview

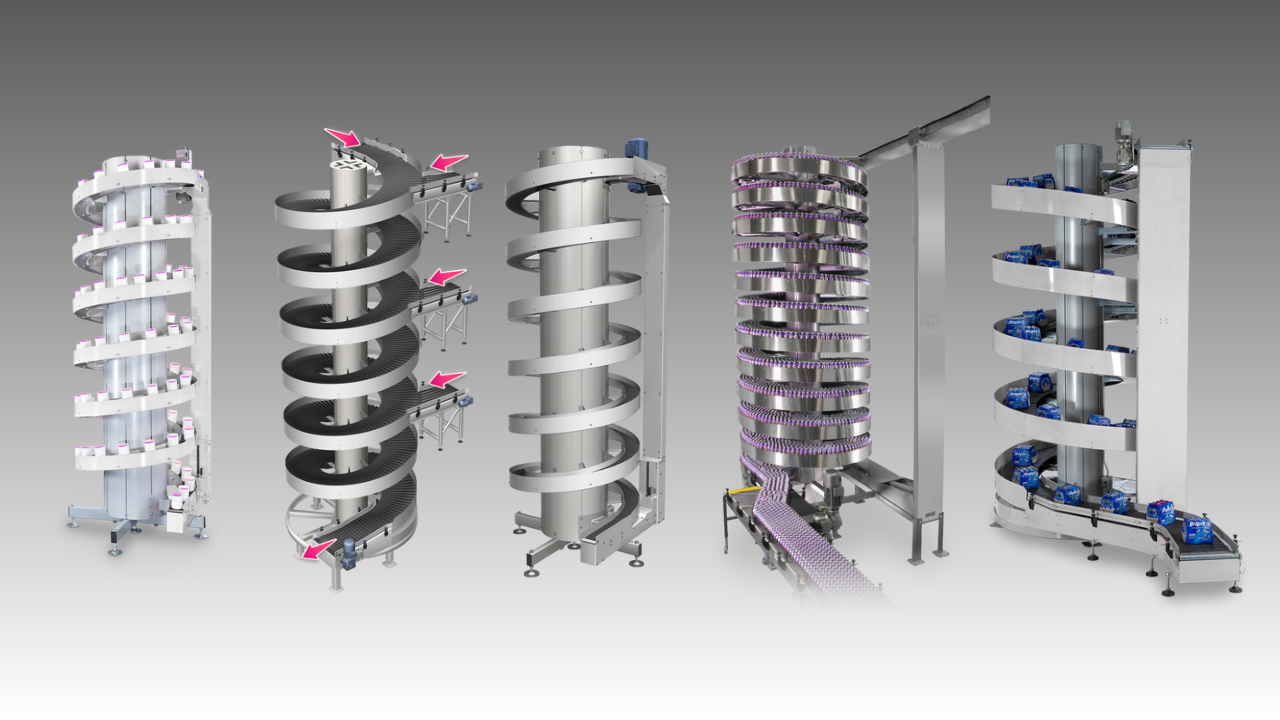

The Ryson Mass Flow Spirals are designed to vertically convey full or empty bottles, cans, jars and similar containers.

The Ryson Mass Flow Spirals are ideal for canning and bottling operations where units need to be conveyed vertically in mass. Products are conveyed up or down in a continuous single file or mass flow at a rate of 2000 units per minute.

Ryson Spirals have a small footprint and provide considerable space savings compared to conventional methods. They are available in powdered coated carbon steel, stainless steel and wet environment versions.

The Mass Flow Spiral conveyors are based on the already proven and reliable Ryson Spiral technology. Only one drive motor is needed, equating to substantial savings in controls and systems integration.

The Mass Flow Spiral conveyors are based on the already proven and reliable Ryson Spiral technology. Only one drive motor is needed, equating to substantial savings in controls and systems integration.

Application Example: Mass Flow Spiral coming off a bulk de-palletizer.

Application Example: Mass Flow Spiral coming off a bulk de-palletizer.

Ryson Spirals for Food and Beverage ApplicationsHigh Capacity Mass Flow Spirals (Models 1900-400 & 2400-500) are able to provide space-savings in bulk de-palletizing of bottles, cans and jars. Use of the Ryson Mass Flow spiral conveyor in conjunction with either high or low-level bulk de-palletizers provides yet another way to increase productivity.

All Ryson Spirals are designed for low maintenance and long life. Many spirals operate 24 hours a day, 7 days a week.

- Gallery

- Features & Benefits

Ryson Spiral Conveyors have many unique features that make them ideal Vertical Conveying Solutions. Many of our features are designed to save money in the long term, essentially lowering your total cost of ownership.

Design Flexibility: Our unique design offers flexibility of configuration. It also adds the ability to field modify to accommodate changing future needs at a fraction of the cost of a new conveyor.

Nesting Slats: provide a smooth and efficient conveying surface, ensuring gentle product handling and suitable for all types of conveyable items. Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

Nesting Slats: provide a smooth and efficient conveying surface, ensuring gentle product handling and suitable for all types of conveyable items. Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

Our innovative chain-slat design enables a low friction operation without any sliding movements or wear-strips. This allows the Spiral to stop and start fully loaded.

Our innovative chain-slat design enables a low friction operation without any sliding movements or wear-strips. This allows the Spiral to stop and start fully loaded.

Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

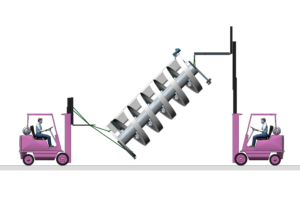

Most Spirals ship in one piece and leave our factory pre-assembled and pre-tested. Installation is generally an efficient process and reduces time for implantation and integration.

Most Spirals ship in one piece and leave our factory pre-assembled and pre-tested. Installation is generally an efficient process and reduces time for implantation and integration.

Our Spirals and components are designed for reliability, low maintenance and long life. They have an impressive up-time record reducing the total cost of ownership.

Click below to read details about more of our features:

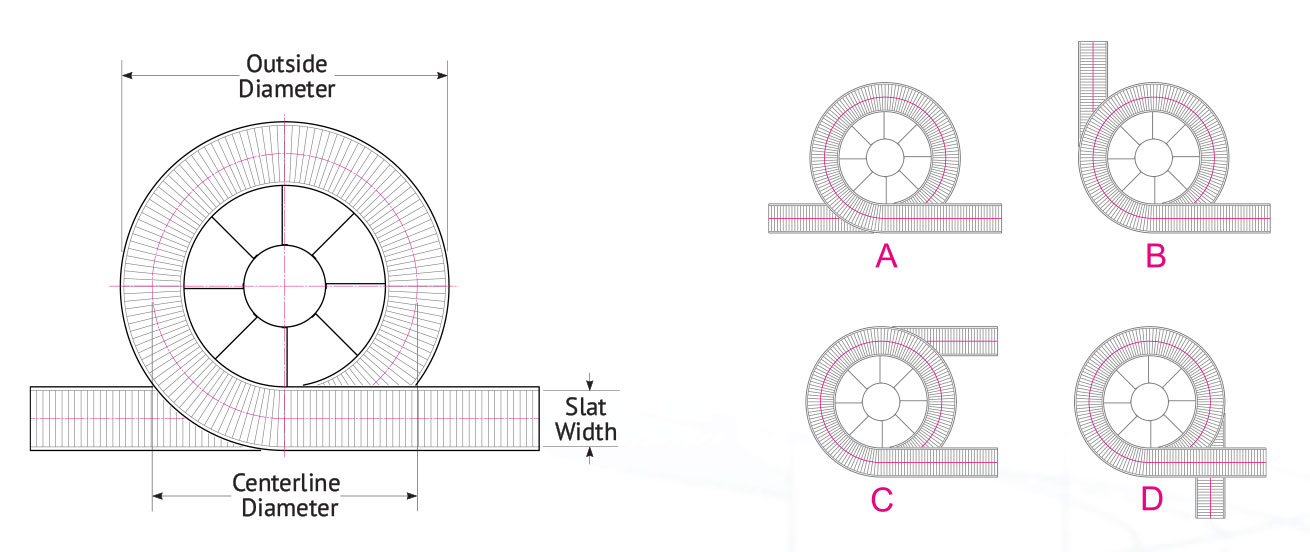

Our innovative modular design allows Ryson to customize any Spiral Conveyor with ease and can also be economically modified in the field to accommodate changing needs. All spiral conveyors are made to order and can operate up or down in a clockwise or counterclockwise rotation and can optionally be reversible. The position and length of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements.

![]() Only one drive motor is required, resulting in substantial savings in energy, controls and systems integration.

Only one drive motor is required, resulting in substantial savings in energy, controls and systems integration.

All Ryson Spiral Conveyors are made to order and comes in a wide range of sizes and configurations.

All Ryson Spiral Conveyors are equipped with an automatic chain tensioning device and built-in overload protection as a standard. This helps save both the Spiral and the product it is conveying.

![]() All Ryson Spirals are designed with a horizontal section at the in and outfeed. This assures a safe and reliable transition between the spiral and adjoining conveyors without product damage and undue wear.

All Ryson Spirals are designed with a horizontal section at the in and outfeed. This assures a safe and reliable transition between the spiral and adjoining conveyors without product damage and undue wear.

The Spiral Conveyors convey loads up or down in a continuous flow, facilitating high throughput. Many spirals can operate at speeds in excess of 200 FPM and are optionally reversible.

Ryson Spirals are powder coated carbon steel with choice of any standard RAL color. They are also available in hybrid versions suitable for wet environments or stainless steel versions for washdown applications.

![]() Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats are made of a nylon composite, need no maintenance and can easily be replaced as single components without the use of special tools. Ryson has a full staff of factory trained service technicians ready to assist. All of our service techs are PMMI Certified Trainers. All of these factors contribute to Ryson’s low total cost of ownership.

Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats are made of a nylon composite, need no maintenance and can easily be replaced as single components without the use of special tools. Ryson has a full staff of factory trained service technicians ready to assist. All of our service techs are PMMI Certified Trainers. All of these factors contribute to Ryson’s low total cost of ownership.

- Specs & Configurations

Most Common Models

Diameter

Diameter

Width

Width

Narrow Trak Spirals

Mass Flow Spirals

- Videos